- OUR IMPACT -

Innovation is all about two things, utilizing the existing and putting them in a new way.

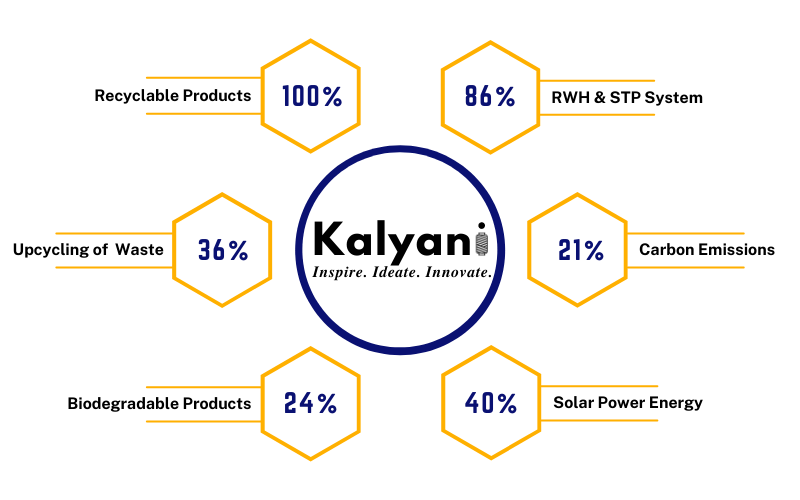

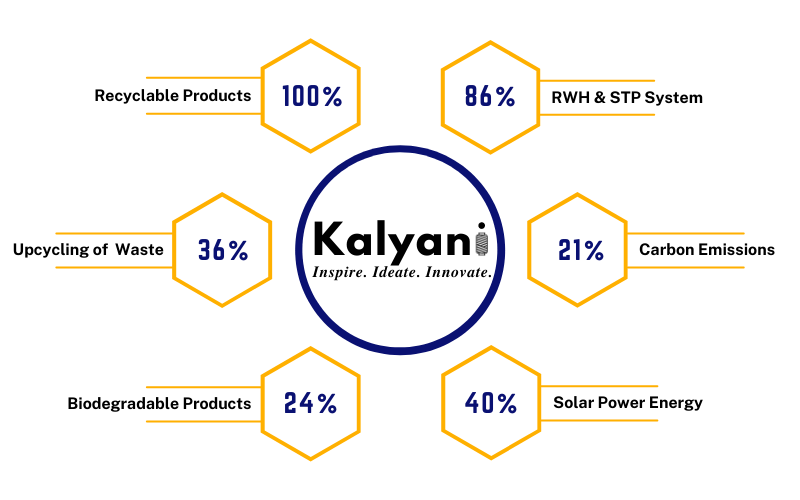

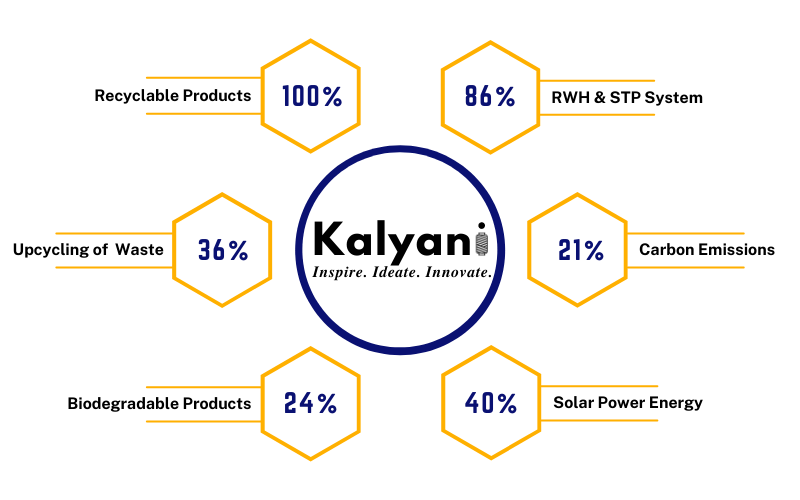

KPPL has installed a Solar Power System on the roof tops of manufacturing and warehouse units. This system is contributing around 40% of the total electrical energy consumptions. The implementation of solar system has eliminated the usage of diesel generators to a greater extent at our manufacturing units. KPPL manufacturing and warehouse units are partly Self-Sustained by producing their own solar energy.

All plastics are not recyclable. But products which are offered at KPPL is 100% recyclable. Recycling of KPPL products is eliminating the dependency on land for disposal, reducing the demand for raw materials and protecting the environment from plastic pollution and is classified as a Green Unit from Central Pollution Control Board.

The waste accumulated during the manufacturing process of certain products are collected and KPPL is transforming these waste materials and other biproducts into a new product of higher quality. KPPL is minimising the volume of discarding materials and waste generated at all manufacturing units and also reduces the need of raw materials for new production.

Asphalt pavements are often subjected to deflections, cracking & ruttings which leads to the failure of pavements. These defects will reduce the mileage of vehicles and increase greenhouse gas emissions due to start and stop movement of vehicles.

One key to improve efficiency of roads is to make pavements that are stiffer. Stiffer pavements reduces the amount of deflections, cracks & rutting’s which in turn reduces wear on the road. But there will be an increase invehicle mileage and reduces greenhouse gas emissions. There are several ways to make roadways stiffer. One way is to add a very small amount of FIBERCRETE to the concrete mix when laying concrete roads.

BBMP, NHAI, MSRDC approved road projects are using FIBERCRETE product as an integral material in their road construction projects. Read more...

KPPL is sourcing a rain water from factory roof tops enclosing an area of 14700 sq mts & diverted towards water storage tanks through the filtered layers. The stored rain water is used for cooling machine plants, toilet flushing, gardening etc. This RWH system at KPPL is providing a substantial savings on water bills.

We have a plan to have a STP in line as per ISO 14001 plans to achieve zero waste targets from KPPL.KPPL has stepped up significantly to reduce Plastic Waste Pollution by implementing Bio-Degradable Plastics in the production line as a Sustainable Development Goal. We can make our products Biodegradable in the coming quarters. And our agricultural products are biodegradable when it is disposed to landfill environments after its intended usage.